How Quick Shield Lifts Sunken Concrete

When you look outside your window, do you see an uneven sidewalk or cracks in your driveway? Foam Tech uses polyurethane foam to lift concrete slabs in the Pacific Northwest. Read below to learn more about the Foam Tech Process.

The Process:

The Quick-Shield process involves drilling one or more small holes in the low area of the slab, then injecting expanding polyurethane foam beneath.

As the foam expands due to a chemical reaction, it pushes the slab back towards its original position. An experienced technician can gauge the expanding action of the foam, controlling the injection process for just the right degree of slab-raising action.

Because the injected polymer material cures quickly, the restored slab can return to its full weight-bearing function within a matter of minutes. Slab repair costs through the Quick-Shield system are far less than replacing the concrete slab altogether.

Quick-shield is installed in a simple 4-step concrete lifting process that results in a safe, secure and level concrete slab. Contact Foam Tech to meet with one of our concrete repair experts. We will inspect your foundation or concrete slab and provide an estimate to have your sunken concrete slab lifted with Quick-shield.

Quick-shield not only results in a solution that looks better and lasts longer, it is less destructive to the applied surface. Mud jacking uses a heavier fill to level the surface and requires a larger quantity of injection holes along with larger sized injection holes.

How does Quick-shield fix sunken concrete? It relies on the unique qualities of expanding polyurethane foam, making it:

- Environmentally safe

- Affordable

- Waterproof to prevent future erosion

- Quick and without mess

- A lasting solution!

In other words, Quick-shield takes the original concept of mud jacking and combines it with modern knowledge and technology.

Step 1.

Small 5/8-in. holes are bored through

the sunken slab.

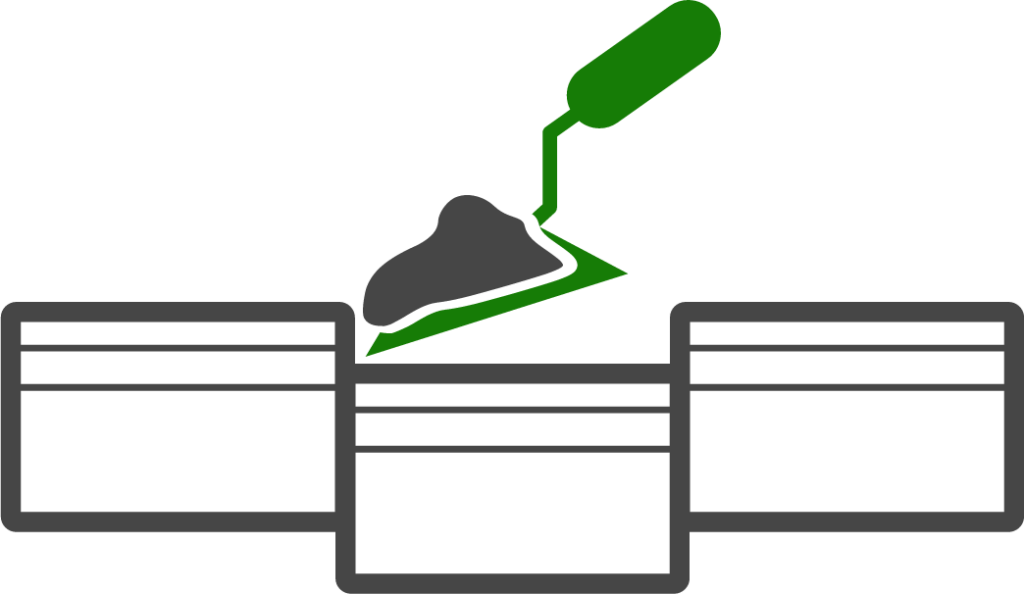

Step 2.

An injector port is installed in each hole.

Step 3.

High-density foam is injected into the

port, where upon it expands and lifts the slab.

Step 4.

With the port removed, the holes

are cleaned and patched with cement.

How Quick Shield Lifts Sunken Concrete

When you look outside your window, do you see an uneven sidewalk or cracks in your driveway?

Foam Tech uses polyurethane foam to lift concrete slabs in the Pacific Northwest. Read below to learn more about the Foam Tech Process.

The Process:

The Quick-Shield process involves drilling one or more small holes in the low area of the slab, then injecting expanding polyurethane foam beneath.

![]()

As the foam expands due to a chemical reaction, it pushes the slab back towards its original position. An experienced technician can gauge the expanding action of the foam, controlling the injection process for just the right degree of slab-raising action.

![]()

Because the injected polymer material cures quickly, the restored slab can return to its full weight-bearing function within a matter of minutes. Slab repair costs through the Quick-Shield system are far less than replacing the concrete slab altogether.

![]()

How does Quick-shield fix sunken concrete? It relies on the unique qualities of expanding polyurethane foam, making it:

- Environmentally safe

- Affordable

- Waterproof to prevent future erosion

- Quick and without mess

- A lasting solution!

In other words, Quick-shield takes the original concept of mud jacking and combines it with modern knowledge and technology.

![]()

Quick-shield not only results in a solution that looks better and lasts longer, it is less destructive to the applied surface. Mud jacking uses a heavier fill to level the surface and requires a larger quantity of injection holes along with larger sized injection holes.

![]()

Quick-shield is installed in a simple 4-step concrete lifting process that results in a safe, secure and level concrete slab. Contact Foam Tech to meet with one of our concrete repair experts. We will inspect your foundation or concrete slab and provide an estimate to have your sunken concrete slab lifted with Quick-shield.

![]()

Step 1.

Small 5/8-in. holes are bored through

the sunken slab.

![]()

Step 2.

An injector port is installed in each hole.

![]()

Step 3.

High-density foam is injected into the

port, where upon it expands and lifts the slab.

![]()

Step 4.

With the port removed, the holes

are cleaned and patched with cement.